Slide Title

IDEAS IN PLASTIC.

Button

Slide Title

TECHNOLOGY AND QUALITY SERVING YOUR IDEAS

Button

Slide Title

FROM DESIGN TO IMPLEMENTATION

Button

Slide Title

CUSTOM-MADE.

Button

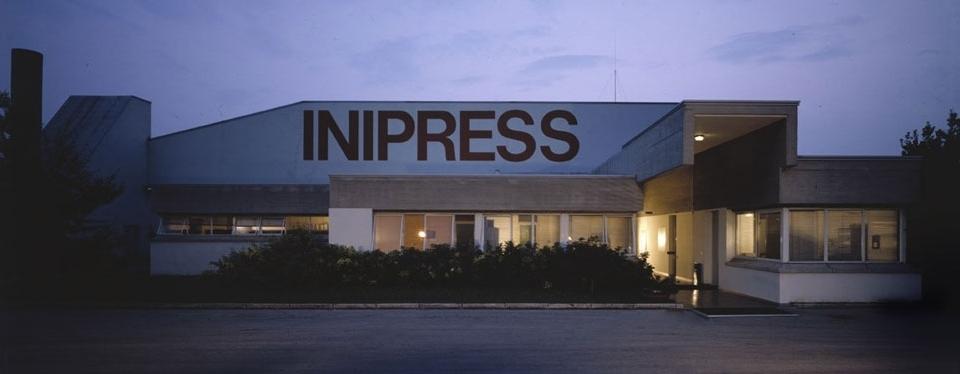

about us

Ideas in Plastic.

Technology and Quality Serving Your Ideas.

Customized Service for Individual Requirements.

INIPRESS' experience in the engineering and production of plastic products through the injection moulding process began in June 1969; as a result of this tradition, our company is a point of reference in multiple sectors, such as foodstuffs, articles for children, furniture-design, motorcycles and industry...

INIPRESS is its customers' success partner thanks to the strategy of market orientation, focus on service and relationships, and its proactive approach.

INIPRESS offers a package of

tailored services to suit customers' needs and expectations: from industrialization, simulation and prototyping through special technologies to screen post processing services, welding, assembly, packaging...

history

- 1969: Giuseppe and Elvira Durante established "Bet Materie Plastiche" based in Gorgo al Monticano which produced furniture components.

- 1970: Partnership with Ferrero began.

- 1974: INIPRESS SpA was established in Motta di Livenza.

- 1985: First transparent rigid plastic boxes for the confectionery business

- 1989: Following the premature death of one of the founders, his wife Elvira Durante became president of the company.

- 1997: Partnership with IKEA was launched.

- 1998: First application of the Gas Assisted Injection molding technology in design furnishing.

- 1999: First application of the bi-injection with family mold for the food containers industry.

- 2001: 1500-ton bi-injection press purchased.

- 2006: Luigi Durante became president.

- 2012: The administrative manager celebrates 40 years of seniority in the company.

- 2013: Deliveries of the first company loyalty tags to the many workers who had supported the company for 40 years.

- 2014: INIPRESS celebrates 45 years of activity in the plastic industry.

ips

INIPRESS PRODUCTION SYSTEM

After having visited Toyota plants and training centers in 2009, INIPRESS decided to review its organisation and processes according to Lean Manufacturing.

Its mission was to become a lean business model, focused on customer value and boosting quality, service and efficiency.

To reach this goal, it invested daily in setting up kaizen mindset for continuous improvement, starting from its own resources and then developing in relations with suppliers and customers.