Slide Title

IDEAS IN PLASTIC.

Button

Slide Title

TECHNOLOGY AND QUALITY SERVING YOUR IDEAS

Button

Slide Title

FROM DESIGN TO IMPLEMENTATION

Button

Slide Title

CUSTOM-MADE.

Button

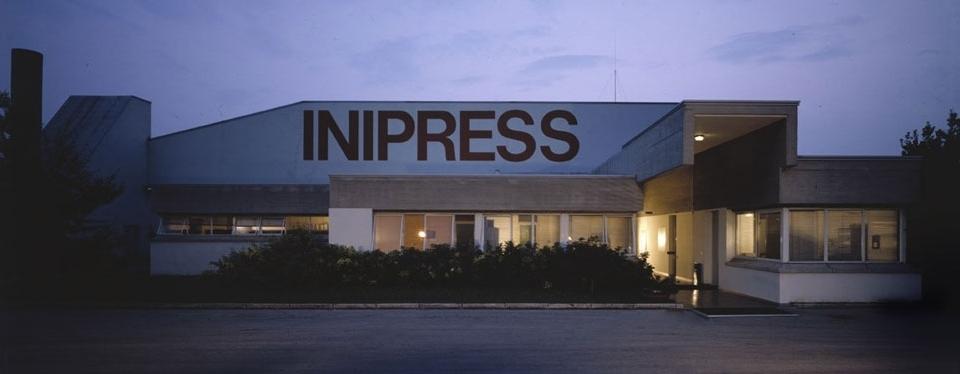

special technologies

INIPRESS gives its customers the opportunity to use the best technologies on the market and highly automated production lines from the arrival of the materials in silo, to the machines through a centralized feeding system, demoulding, quality control, assembly and palletizing.

Examples include:

• Bi-injection moulding (2K), tri-injection (3K)

(Production of multicoloured or multi-material components in a single cycle)

• InMouldLabelling

(Production of components with labels and/or graphics merged in plastic)

• Gas assisted injection moulding

(Production of hollow components and/or with reinforcing structures or thickenings limiting defects due to material shrinkage on the visible surfaces)

• Thin wall injection moulding

(Production of very light components reducing the use of the raw material)

• Fabric inserts or metal over moulding

(Production of multi-material components, i.e Velcro inserts...)